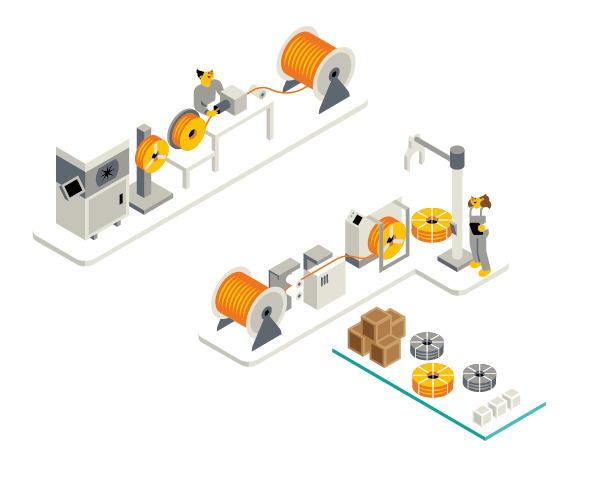

Maximum efficiency in every production step

Our production process is designed for maximum efficiency. We track every order from start to finish and ensure regular communication between internal departments, providing our clients with a precision-managed service, from initial consultation to final delivery.

RESEARCH AND DEVELOPMENT

This department works closely with the sales team, which represents a direct link to customer needs.

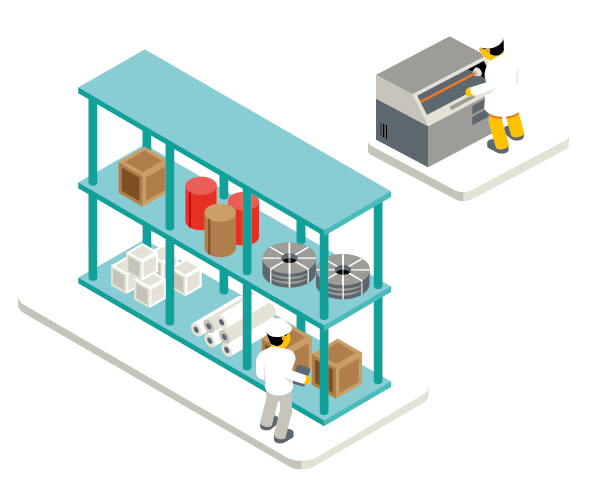

QUALITY DEPARTMENT

The Quality Department checks all incoming material (raw materials, thermoplastic polymers, textile fibers, aramid fibers, steel wires and fittings). Quality Control is also responsible for the inspection and validation of the hose production procedure. During the various stages of hose production (extrusion, reinforcement, outer cover extrusion, packing, hose assembly) samples of the product are collected and tested.

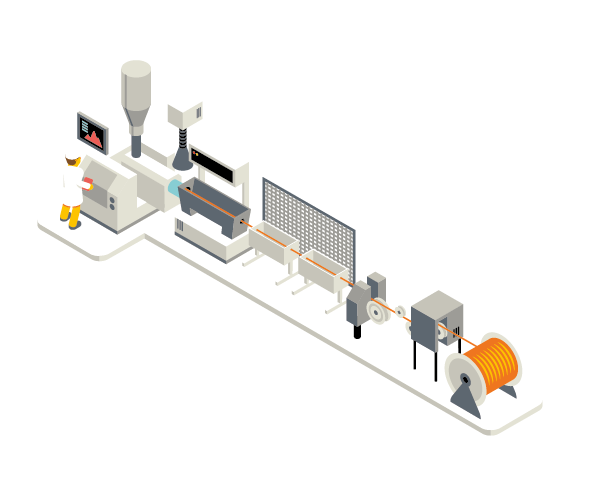

TUBE EXTRUSION

Production starts with the extrusion of an inner tube forming the first hose layer. Then tube-reinforcement follows. It can be done using one of two techniques: braiding or spiraling.

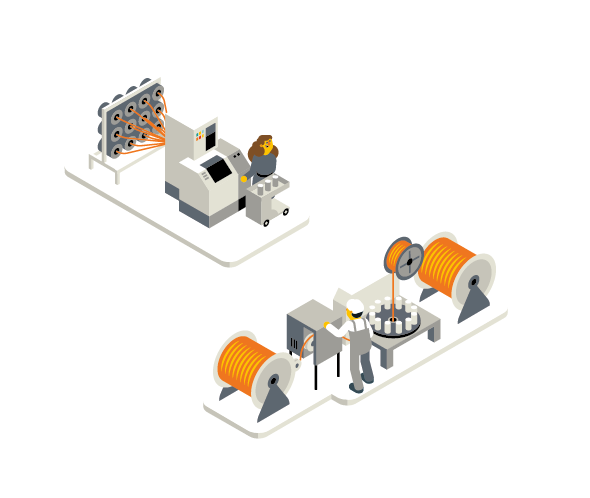

REINFORCEMENT

Braiding is the soul of the reinforcement that assures pressure resistance. After being braided, the Gomax hose is then extruded once again, adding one more layer as protection from external attacks.

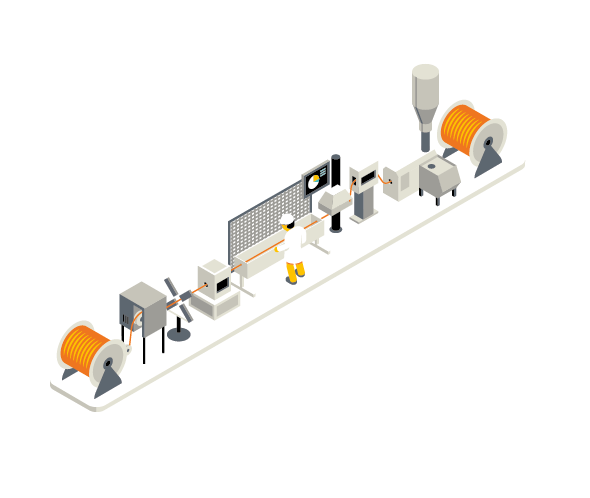

COVER EXTRUSION

Once all the reinforcement layers are applied, the cover extrusion closes the hose manufacturing process. It consists in applying an extruded outer cover that protects the hose from abuse or external agents such as abrasion, fluids, chemical substances, temperature variations and weathering.

PACKING AND ASSEMBLING

After being produced, the Gomax hose is packaged for sale as per the customer’s requirements. The finished product can be supplied in 10 or 50 meters coils, or can be further worked by producing a hose already fitted and ready for use.