Quadra DN6

Flexible thermoplastic capillary hose with 6mm internal diameter

Orange

Black

UL Approved

10m

50m

| Part no. | Color | Pack | Description | |

|---|---|---|---|---|

| 0786C |  |

50m 50m |

Orange UL approved hose in 50m coil |

Add to wish-list

|

| 0786BC |  |

50m 50m |

Black UL approved hose in 50m coil |

Add to wish-list

|

| 0786K |  |

10m 10m |

Orange UL approved hose in 10m coil |

Add to wish-list

|

| 0786BK |  |

10m 10m |

Black UL approved hose in 10m coil |

Add to wish-list

|

Technical Features

| Hose Diameters | ID 6mm0.236in |

OD 10.9mm0.429in |

| mm | inch | |

|---|---|---|

| Bend radius | 35 | 1.377 |

| Hydraulic Plier Crimping Diam. | 12,4 -0,1 12,4 +0,2 |

0.488-0.0039 0.275+0.0039 |

| Electric Plier Crimping Diam. | 12,4 -0,1 12,4 +0,2 |

0.488-0.0039 0.275+0.0039 |

| bar | MPa | Psi | |

|---|---|---|---|

| WP | 120 | 12.0 | 1740 |

| BP | 600 | 60 | 8700 |

| min | max | |||

|---|---|---|---|---|

| WT | -45°C | +130°C | -49°F | +266°F |

Download

Permitted

Fluids

| Type of gas | Type of oil |

|---|---|

| HFO/HFC (R134a, R404A, R407A, R407B, R407C, R410A, R507, R32, R448A, R449A, R450A, R513A, R1234yf, R1234ze) | polyol ester based |

| HCFC (R22) | mineral oils |

| CO2 | polyol ester based |

| NH3 - Ammonia Use only inox ferrules and fittings |

Mineral Oils and Polyalphaolefin (PAO) |

Classification of QUADRA capillary hoses

| Part no. | Classification according to Directive 97/23/CE |

|---|---|

| 0786C | paragraph 3 article 3 |

| 0786BC | |

| 0786K | |

| 0786BK |

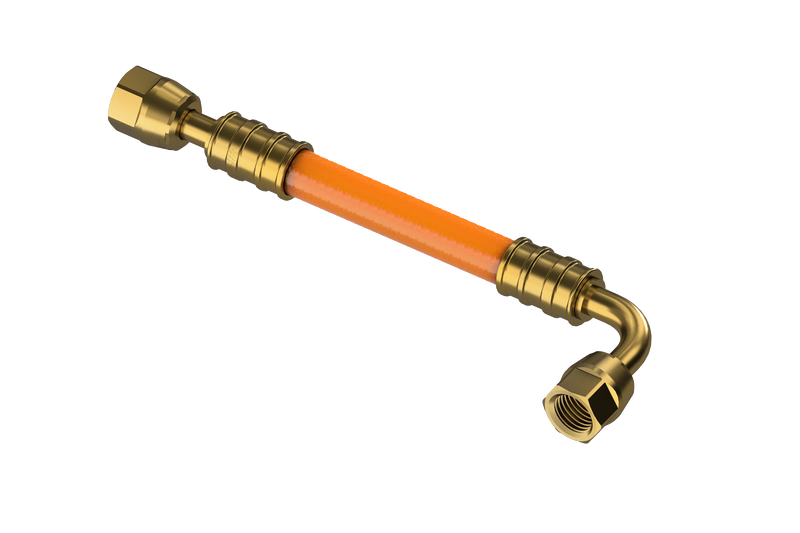

DN6 fittings

The large fitting range available and the dedicated assembly tooling for the QUADRA hose allows the operator to assemble the machine, or carry out maintenance and to work quickly, flexibly and securely.

1/4 SAE con 1/4 SAE 7/16-20 UNF thread straight female fitting – conforms to UL requirements

|

Part number

|

Item

|

Copper gasket

|

|

|---|---|---|---|

| XBA02N | 50 pieces box |

Add to wish-list

|

|

| WBA02N | 50 pieces box |

Add to wish-list

|

|

| KBA02N | 10 pieces blister |

Add to wish-list

|

3/8 SAE 5/8-18 UNF thread straight female fitting

|

Part number

|

Item

|

Copper gasket

|

|

|---|---|---|---|

| XBA04N | 50 pieces box |

Add to wish-list

|

|

| WBA04N | 50 pieces box |

Add to wish-list

|

|

| KBA04N | 10 pieces blister |

Add to wish-list

|

1/4 SAE 7/16-20 UNF thread female 90° – conforms to UL requirements

|

Part number

|

Item

|

Copper gasket

|

|

|---|---|---|---|

| XCA02N | 50 pieces box |

Add to wish-list

|

|

| WCA02N | 50 pieces box |

Add to wish-list

|

|

| KCA02N | 10 pieces blister |

Add to wish-list

|

3/8 SAE 5/8-18 UNF thread female 90° – conforms to UL requirements

|

Part number

|

Item

|

Copper gasket

|

|

|---|---|---|---|

| XCA04N | 50 pieces box |

Add to wish-list

|

|

| WCA04N | 50 pieces box |

Add to wish-list

|

|

| KCA04N | 10 pieces blister |

Add to wish-list

|

Copper brazing fitting (6x8x100mm)

|

Part number

|

Item

|

|

|---|---|---|

| WZE2N1 | 50 pieces box |

Add to wish-list

|

DN6 Accessories

The assembly tooling for the QUADRA hose allows the operator to assemble the machine, or carry out maintenance and to work quickly, flexibly and securely, reducing to a minimum the need of brazing operations.

Pliers

Battery hydraulic crimping machine 45 kN

Battery Li-Ion 18V 1.5Ah

Battery charger

.png)

USB cable and Software (CD)

Set of dies DN2, DN4 and DN6

Case

Spare Li-Ion 18V 1.5Ah battery

DC bench power supply

Total weight: 6,5 Kg

Cutter and Blades

Gasket and nut caps

QUADRA Case

DN6 Assembled

Assembled hose in bundles of 50 pieces

Orange

Black

UL Approved